J22 – Cobbling together a modern fighter aircraft

Early in 1940 Sweden had placed large orders with American aircraft manufacturers. Namely, 120 Seversky EP-106 and 144 Vultee P66 Vanguard were on order, with Swedish designations J9 and J10. The Swedish designation “J” is for “Jakt”, meaning “Fighter”. Suddenly there was a threat that the USA would forbid military weapon exports to Sweden, even though for a long time Sweden hoped this would not happen.

Sweden was searching everywhere for modern fighter aircraft, even making enquiries with the Soviet Union, which was producing a number of promising aircraft, such as the Yak-9 which caught Swedish interest. But whilst at that time the Soviet Union was undergoing a modernisation phase, they could only offer the older I-16 fighter aircraft that was similar to the Swedish J9, and nothing better. Finland was involved with her own project, the Myrsky fighter, but neither that nor the closely related Pyry could meet the Swedish requirements.

Perhaps the most fantastic alternative was that Japan, via her Air attaché in Stockholm thought that Sweden would be able to purchase a development of their famous Mitsubishi AM6Zero fighter aircraft. However this project had to be abandoned due to the fact that transportation to Sweden could not be guaranteed. At least the thought of a Swedish Zero was a fascinating idea.

The temporary solution came, as already described in the section on the search by the Swedish Air Force for modern fighters, in the purchase of the Fiat Cr42 (J11) and Reggiane Re 2000 (J20) to fill the Swedish fighter gap.

Indigenous aircraft

Nowadays the Swedish aircraft industry is synonymous with SAAB (now called Saab), but this has not always been the case. In the 1920s and 1930s several small aircraft companies sprang into life. The company Svenska Aero constructed the Jaktfalken fighter, which when it was launched in 1929 was equal to the best elsewhere. However only 19 of all its variants were built. The last seven were built by ASJA in 1933, which by then had bought up Svenska Aero. ASJA stood for Aktiebolaget Svenska Järnvägsverkstädernas Aeroplanavdelning (Swedish Railway Workshops Aeroplane Department Limited Company). It may today seem strange that a railway vehicle manufacturer turned to the manufacture of aircraft, but between the wars aviation was the great hope of the future, a little like the IT industry became in the 1990s. So there were many who wanted to get into this branch. ASJA was however particularly important, as several of its projects came to mature when the company became part of the organisation that in March 1939 founded the company Svenska Aeroplan AB (Swedish Aeroplane Company Limited) the was known by its abbreviation as SAAB, and today Saab.

Another of the companies working in this field was Sparmannverkstäderna (The Sparmann Workshops) which was founded by one Edmund Sparmann and functioned between 1932 and 1937. Eventually the legacy of Sparrmanverkstäderna also helped to form SAAB.

One of the engineers who was engaged in this pioneering phase of Swedish aircraft manufacturing was Bo Lundberg. He graduated in engineering in 1931 and then worked as a designer, first with ASJA and then with Sparmann. At Sparmann he took part in a project that has gone down in history as the Sparmann fighter, which was an early monoplane type fighter aircraft. However it never got further than the drawing board. From 1939, at the age of 32 he got the job of manager of the Götaverken Aeroplane department. Götaverken was one of Sweden’s major shipbuilders and it may seem strange, just as in the case of ASJA, that a company that built large ships went in for aircraft manufacture. But that was how it was in those days.

Götaverken’s aircraft manufacture was bedevilled by problems due to inexperience, but also by its late arrival on the scene and sheer bad luck. The company licence-built a number of B4 Hawker Hart aircraft for the Swedish Air Force, but the project became delayed so much, partly due to inexperience, but also because Hawker’s were so slow to send the necessary drawings that the Air Force was no longer interested in doing business with Götaverken. But there were also other interests, namely the newly-founded SAAB who had support from powerful political and business interests who made sure of ongoing co-operation with the Air Force.

Götaverken managed to built a small series of licence-built private aircraft called the Rearwin Sportster, under its own designation of GV38, but only managed to build 14 before the outbreak of World War 2. Under Bo Lundberg’s management Götaverken had started two projects, the other being the GP8, which was a fighter. SAAB also started to prepare for a fighter, to be called the J19, but this had to be put aside when they began to focus on the SAAB B17 dive bomber (“B” meaning “Bomber”).

The SAAB B17 was a light bomber, developed by the SAAB company.

Once war had broken out, Götaverken’s interest in building aircraft declined. It was after all a shipbuilder and had to focus that kind of work instead. But Bo Lundberg would benefit after all from the discarded fighter aircraft project. He would now work in the inspection group that kept an eye on Sweden’s aircraft orders in the USA, first with Seversky and later, as the head of the inspection group, with the Vultee Aircraft Company. It was while he was still in the USA at Vultee in the summer of 1940, when it became clear that the export permission for their aircraft was under threat, that the head of department at the Aviation Administration, Nils Söderberg, contacted Bo Lundberg. Söderberg asked Bo Lundberg to start to sketch out a completely Swedish fighter aircraft and also to prepare to go home. Bo Lundberg started the project immediately, and after he had returned to Sweden in October 1940 he already had a draft ready for what would become the J22.

However it was obvious from the start that it would not be possible to continue with the GP9, as it was intended to be an aluminium aircraft, and all the available aluminium was being used by SAAB for the B17. Nevertheless, parts of the GP9 project did remain embedded in the forthcoming J22 design. Of course he had to find a solution regarding other material, which left steel and wood, but how? It is said that Bo Lundberg hit on the solution as he was relaxing on the sand at Long Beach in California.

Steel is heavy but strong. So the solution would be to build a steel skeleton in the form of a truss framework, both for the fuselage and the wings. The outer skins would then be made of birch wood veneer, which would have to be well secured to the steel skeleton in order to attain the required strength. In this way there would be the required combination of the light weight of the veneer and the strength of the steel. There was a long way to go, but at least there was now a plan. The question was just who would build the aircraft and all its components, since SAAB was not able to take on another project.

Who would build the aircraft?

Bo Lundberg already had a proposal for the new fighter aircraft when he returned to Sweden. There were clearly limitations. When he sketched out the GP9 he had planned that the aircraft would be powered by a 1,400 horsepower Bristol Taurus 14-cylinder two-row air-cooled radial engine, and calculations showed a possible maximum speed 682 km/h (424 mph) which was very fast at that time. However the engine that could be made available for the J22, and even this was very doubtful, was the similar configuration Pratt & Whitney Twin Wasp of 1,065 horsepower.

In order to be able to seriously start the project it was necessary to find someone who could actually build the aircraft. Nils Söderberg had become the manager of the development programme, and in order to move forward created a temporary organisation called the Flygförvaltningens Verkstad Stockholm (Flight Administration Workshops Stockholm – FFV Stockholm). Bo Lundberg became the manager of the FFVS Technical Office and at the beginning of January presented the preliminary draft of what would be called the P22.

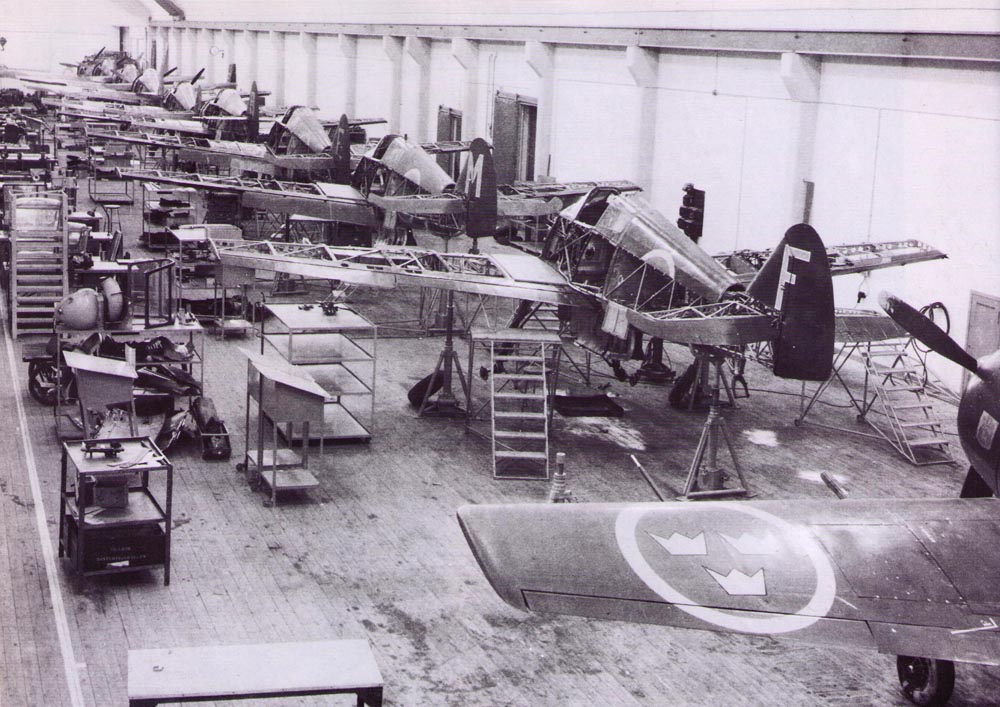

With the support of Nils Söderberg the project continued, and in October 1941 received permission for further development, so on December 11th the first of two prototypes was ordered. These were now built by hand in the FFVS Bromma, Stockholm workshops. The parts had to be specially made and also carefully measured for subsequent series production. It was clearly apparent that the fabrication had to be spread among many small manufacturers, of whom most had no previous experience of aircraft manufacturing. Progress was very quick because already in March 1942 the Swedish Air Force ordered a first batch of 60 aircraft! This was 6 months before the first prototype took off for its first test flight!

It was arranged for the aircraft to be assembled at the ABA airline hangars at Bromma, Stockholm, and altogether approximately 500 subcontractors were involved. These needed detailed drawings, and out of the 17,000 parts making up a J22, 12,000 were made by subcontractors all over Sweden. Some had experience of vehicle manufacturing, such as Hägglund & Söner in Örnsköldsvik, who put together the steel tubing truss assembly for the fuselage. The wing spars and other metal components for the wings were manufactured and welded together by Sefabrik at Sandviken and by AGA at Lidingö, Stockholm. For the moulded wood veneer that covered the fuselage and wings special competence was necessary and this was found at the furniture manufacturer Möbelfabriken in Bodafors and at NK in Nyköping. Much of the electronics was made by Uno Särnmark in Gothenburg and Nordiska Armaturfabriken (NAF) manufactured most of the instruments.

As earlier mentioned, the list of subcontractors was much longer, and this was the system that made the construction of the J22 possible. Some people today believe that the high quality Swedish industrial base was born as a result of this project.

After preliminary tests on the ground, the first flight of the prototype, 22001, took place on September 20, 1942. By that time the manufacture of components for series production had already begun. This was in itself rather risky, but it did save a lot of time. The main holdup was really the access to engines, which looms large in the in the account of the Air Force’s attempts to purchase modern fighter aircraft in the first year of the War. Svenska Flygmotor put in intensive work from the ground up to set up production of a pirate copy of the Pratt & Whitney Twin Wasp engine in Sweden, although the first batch of these engines came from a number that Germany had taken as war booty in France, and that Sweden had finally managed to purchase in the summer of 1943.

A J22 of No. 10 Wing based at Ängelholm, southern Sweden.

Into Air Force service

On September 1st 1943 the first J22 aircraft were delivered to No. 9 Wing, Kungliga Göta flygflottilj at Säve outside Gothenburg. It was at that time the fastest aircraft in Swedish service, attaining a maximum speed of 575 km/h (360 mph). This speed was completely comparable to that of the most modern fighter aircraft in 1940 and 1941. However development went forward at breakneck speed during the War and in 1943 there were many aircraft, such as the de Havilland Mosquito, that could reach well over 600 km/h (370 mph). The J22 armament consisted of two 7.9 mm machine guns in the nose and two 13.2 mm cannons, one in each wing. This was relatively modest compared to contemporary single-engined fighters, which had at least two 20 mm cannons and 2 or 4 machine guns of various calibres. Some aircraft could boast four 20 mm cannons. In order to increase their firepower, later built J22s had the machine guns in the nose replaced by a further two 13.2 mm cannons.

However a closer look at the Swedish 13.2 mm automatic cannon shows it in a rather different light. Weapons of similar calibre were in use elsewhere, such as in the USA, which made its 12.7 mm (0.5 inch) machine gun something of a standard weapon within its air force. It was however a question of a machine gun, that could of course fire heavy explosive ammunition or incendiary bullets, or alternatively the ability to fire a solid bullet that could penetrate a long way but in principle only made a hole. A cannon is characterised as being able to fire shells as standard ammunition, i.e. projectiles that most commonly explode on impact or immediately after penetrating the target. Cannons were usually of 20 mm calibre and the aircraft carried a smaller number of projectiles than for a machine gun. The difference was that one hit would be enough to bring down an aircraft, even if it struck a relatively less vital part. An explosive shell could, with luck, shear off a wing, that could otherwise take several strikes from machine gun bullets and continue to fly.

The Swedish m/39 13.2 mm cannon combined a rate of fire and the possibility to load more ammunition with the more effective ammunition. This meant that the Swedish weapon, thanks to its greater rate of fire was comparable to the 20 mm cannons used by other countries. In this respect therefore, Sweden had a slight advantage when it came to aircraft firepower. Fortunately this never had to be tested in battle.

The J22 was very manoeuvrable, which was an important factor in dogfights against other fighters.

When No. 9 Wing became the first Swedish unit to be equipped with the J22 there was a certain symbolism. No. 9 Wing was originally to receive the J9, which never came to Sweden, an event that started the J22 project. That Wing had first flown the J8 Gloster Gladiator, a type that they took over from No. 8 Wing at Barkaby, Stockholm and then the Italian Fiat CR42 (J11) biplanes, which happened to be the slowest fighter aircraft in Swedish Air Force service. The step from the Italian biplane to the J22 monoplane was therefore enormous and well deserved, despite the delay. With the J22 the Swedish Air Force finally had at least a respectable fighter aircraft.

It could be interesting to play with the thought of what Bo Lundberg could have achieved if he had had access to the engine on which he had based his GP9, the 1,400 horsepower Bristol Taurus. The GP9 had an estimated top speed of over 620 km/h (385 mph). With its more modest Twin Wasp the J22 came up to 590km/h (367 mph). With a more powerful engine the J22 could perhaps have been an aircraft that could measure up to the best, even at the end of the War in 1945.

Now Sweden was able, in connection with the purchase of the American P-51D Mustang (J26) the possibility of testing the capabilities of the J22. After the tests it is claimed that the American pilots had said, “Why the hell did you buy the Mustang when you have this?”

The P-51D Mustang was successful and several are still flying as vintage aircraft. This was at an air show in Borås, southern Sweden. Photo and copyright Peter Langsdale

The J22 showed itself to be superior in a dogfight and could climb faster than a Mustang up to 1500 metres (5,000 feet) height. But with its 1,700 hp engine which gave the Mustang a top speed of over 700 km/h (435 mph), combined with a long range and heavier armament, the Mustang was a better aircraft overall. The speed advantage made it possible for the Mustang to decide when to give battle and to adapt its tactics if necessary to avoid a dogfight scenario.

Nevertheless the J22 could give a good enough account of itself to have impressed the American pilots sufficiently to give it high marks, especially considering the limitations that Bo Lundberg and his colleagues were forced to work within.

After the War – the J22 is almost offered second-hand

When the Second World War ended in Europe in May 1945, not all of the 198 J22 aircraft that had been ordered had been delivered to the Swedish Air Force. A number of J22 aircraft had been rebuilt to serve as reconnaissance aircraft with the designation S22, although there was no new production of this variant. Needs had reduced after the War and there was much wartime material for sale by the victorious combatant nations. In addition, a decision had been made at the highest level that all development of propeller-driven aircraft should crease and all focus placed on developing military jet aircraft. This decision led to SAAB as early as 1948 being able to present a flying prototype of the SAAB 29 “Flying Barrel”. In 1952 the J22 was withdrawn from service and the following year even the J26 Mustang followed suit. An epoch in Swedish aviation history had drawn to a close.

J22 aircraft being rebuilt as the S22 model at Arboga, central Sweden.

However a number of J22 aircraft almost gained a new life in a different air force. Sweden sold many of its pensioned off J26 Mustangs to Central American countries. As propeller-driven aircraft go, the Mustangs offered excellent performance and for poorer countries who could not afford the new jet aircraft second-hand Mustangs were an excellent alternative, not least because their neighbours often didn’t have enough money to buy jet aircraft either.

One country that showed interest in the J22 was Ethiopia. After the Second World War that country was attempting to build up an Air Force. Here too the cost of jet aircraft was too high to start with, but Ethiopia had a special relationship with Sweden, After the War off-duty personnel from the Swedish Air Force under the leadership of Carl Gustav von Rosen offered support by building up the Ethiopian Air Force that between 1947 and 1950 purchased second-hand SAAB B17 dive numbers, which remained in Ethiopian service until 1968. Since the J22 used the same engine as the SAAB B17 Ethiopia asked in 1949 if it could buy a number of J22s in order to set up a fighter squadron. Although this did not come to pass, many Swedes nevertheless worked for the Ethiopian Air Force for several more years.

The J22 has to some extent faded into obscurity, probably because it was not built by SAAB and thereby did not figure in the success saga that SAAB enjoyed. A name can mean so much. But considering what the project group around the J22 had to put up with, the J22 should have deserved better. However this aircraft did contribute to what would become the Swedish aviation wonder, not least because so many companies, large and small, could try out aviation technology and discover the precision it required.